|

-

STEIGENTECH

POWERPLUS™

NARROW WEDGE V-BELT

50% MORE POWER THAN A STANDARD WEDGE V-BELT

Proven better performance

Steigentech POWERPLUS™ Narrow Wedge V-Belts are specially constructed to deliver higher performance than all other

standard narrow wedge V-belts. Tests have determined that they are particularly suited to heavy-duty applications and industrial machines.

Ideal for lower temperature applications

Steigentech POWERPLUS™ Narrow Wedge V-Belts combine transversal polychloroprene and a heavy-duty wrapping cover, which makes them ideal for

extreme low temperatures - down to -40 °C. The material design has good resistance to abrasion, dust and other external aggressors, including mineral oil, ozone and UV.

International Standards

- Manufactured to ISO 4148, RMA/MPTA.

- Designated to be used with V-pulleys according to DIN2211.

- Electrically conductive in accordance with ISO 1813.

- Meets RoHs and REACH requirements.

Single and banded versions are now

available - up to max 25 ribs.

------------------------------------------------

Sections Length (mm)

------------------------------------------------

SPZ 1,000-5,000

------------------------------------------------

SPA 1,000-5,000

------------------------------------------------

SPB 1,270-15,000

------------------------------------------------

SPC 1,380-12,500

------------------------------------------------

3V 1,000-4,700

------------------------------------------------

5V 1,270-15,000

------------------------------------------------

8V 2,000-15,000

------------------------------------------------ -

STEIGENTECH

POWERPLUS™

EPDM CRE V-BELTThis advanced EPDM V-belt is a high-performance product that incorporates high tensile cord to ensure improved energy efficiency

and drive performance, with maintenance-free operation that allows installation without retensioning, reducing downtime and replacement costs.

Lower tension decay, minimal stretch and high flex capability, the STEIGENTECH POWERPLUS™ EPDM CRE V-Belt operates under a broad range of low and

high temperatures (-40 °C to +130 °C) and is ideal for systems with compact designs.

International Standards

- Manufactured to DIN 7753, ISO 4148, RMA IP-22

- Electrically conductive in accordance with ISO 1813

- Meets RoHs and REACH requirements.

Single and banded versions are now

available - up to max 10 ribs.

--------------------------------------------

Section Length (mm)

--------------------------------------------

ZX/XPZ 620 - 2,570

--------------------------------------------

AX/XPA 620 - 2,565

--------------------------------------------

BX/XPB/5VX 625 - 2,815

--------------------------------------------

CX/XPC 645 - 2,825

-------------------------------------------- -

STEIGENTECH

POWERPLUS®

RUBBER TIMING BELTProven Better Performance

Steigentech POWERPLUS® Rubber Timing Belts are tailored to deliver higher performance than any other standard rubber timing belt, with different belt profiles

available for both light and heavy duty applications. When operating at high load and speeds up to 50 m/s, power rating tests show up to 200% more power load

capacity than standard rubber timing belts. Their temperature performance range of -20 °C to + 100 °C makes them ideal in even the most tropical

conditions. Especially resistant to ozone and ageing, Steigentech POWERPLUS® Rubber Timing Belts also show tolerable resistance to oil and water.

International standards

- Conforms to ISO 5296 (Imperial Trapezoidal),

ISO 17396 (Metric Trapezoidal) and

ISO 13050 (Curvilinear)

- To be used with standard pulleys of their

respective profile

- Electrically conductive/Anti Static to ISO 9563

- Tested to be Silicon Free and suitable for

Automotive Production Lines and other paint

applications

- Highly resistant to ozone, abrasion and ageing

- Meets RoHs and REACH requirements.

Available Ranges: Over 1.000 moulds available.

Imperial Classical Trapezoidal Tooth

- Profiles: XL, XH, XXH, L & H

Metric Classical Trapezoidal Tooth

- Profiles: T5 & T10

Curvilinear Tooth

- Profiles: 3M, 5M, 8M & 14M

S3M, S5M, S8M & S14M

R3M, R5M, R8M & R14M

Double Sided Curvilinear Tooth

- Profiles: D8M

Open Ended Curvilinear Tooth

- Profiles: OE-3M, OE-5M, OE-8M

OE-S5M, OE-S8M & OE-14M

OE-3MGT, OE-5MGT, & OE-14MGT

OE-L & OE-H (Trapezoidal Tooth) -

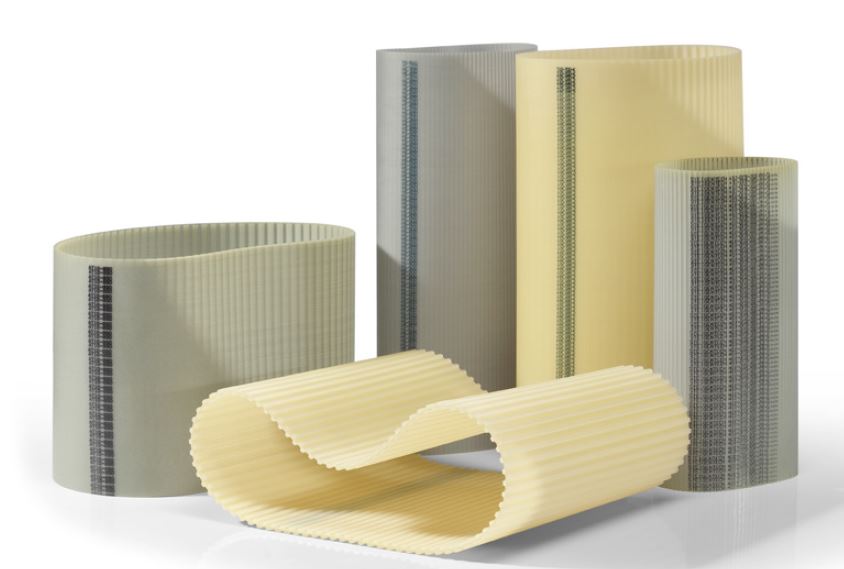

STEIGENTECH

POWERPLUS™

PU TIMING BELTBetter wear- and temperature-resistance

A cleaner alternative to rubber timing belts for applications including the food and robotics

Steigentech POWERPLUS™ PU Timing Belts are resistant to oil and extremely durable. In tests, they outperformed equivalent competitive products by up to 30% in wear resistance and strength. With a temperature range of -30 °C to +80 °C, the Steigentech POWERPLUS™ PU Timing Belt can operate at a sustained peak of up to 110 °C.

Extreme quality stabilityProduced using an advanced thermoset moulding process, Steigentech POWERPLUS™ PU Timing Belts deliver peace of mind through repeatability and consistency of quality. The specially-developed precision-moulding endless-PU-process ensures high pitch precision across the entire belt. Exact replication of fine contours makes this process particularly suitable for small pitches.

International Standards

- Manufactured to DIN/ISO 5296 Parts 1&2 /

IP24 RMA-MPTA (Imperial) and DIN 7721 -

ISO 13050/IP27 RMA-MPTA (Metric)

- Non static conductive

- Maximum oil and ozone resistance

- Heat resistant, support flex fatigue

- Meets RoHs and REACH requirements.

Imperial Classical Trapezoidal Tooth

- Profiles MXL, XL, L, and H

- Manufactured to DIN/ISO 5296 Part 1& 2,

IP24 RMA-MPTA

Metric Classical Trapezoidal Tooth

- Profiles T2.5, DT2.5, AT5, T5, TA5, T10,

DT10 & AT10

- Manufactured to DIN 7721, ISO 13050,

IP27 RMA-MPTA

Curvilinear Tooth

- Profiles 2M, 3M, 5M, 8M, S2M, S3M, & S5M

- Manufactured to DIN 7721, ISO 13050,

IP27 RMA-MPTA.